Last update 20/04//2020 - 16:15

A major step forward towards sustainability

DEMO phase's fleet in the 2 ha microalgae ponds area.

Bird’s eye view of the All-gas Demo plant

Demo phase – A cultivation area of more than 2 ha

All-gas car's refueling

CNG cars moved by the All-gas project biogas produced in El Torno WWTP

Consortium members, in front of El Torno WWTP in the annual meeting (may 2012)

One of the challenges that R&D faces in the water sector is to take maximum advantage of the residuals produced at the different stages in the water cycle. Our aim is to achieve the highest possible degree of sustainability and efficiency.

With current technology, wastewater treatment involves high resources expenditure and, conversely, minimum reuse of the energy these processes could provide. One of our most ambitious lines of research examines using wastewater as a key factor in obtaining biofuels. If possible, this would revolutionize the current wastewater treatment paradigm: what had, until now, been considered an undesirable by-product would become a valuable resource.

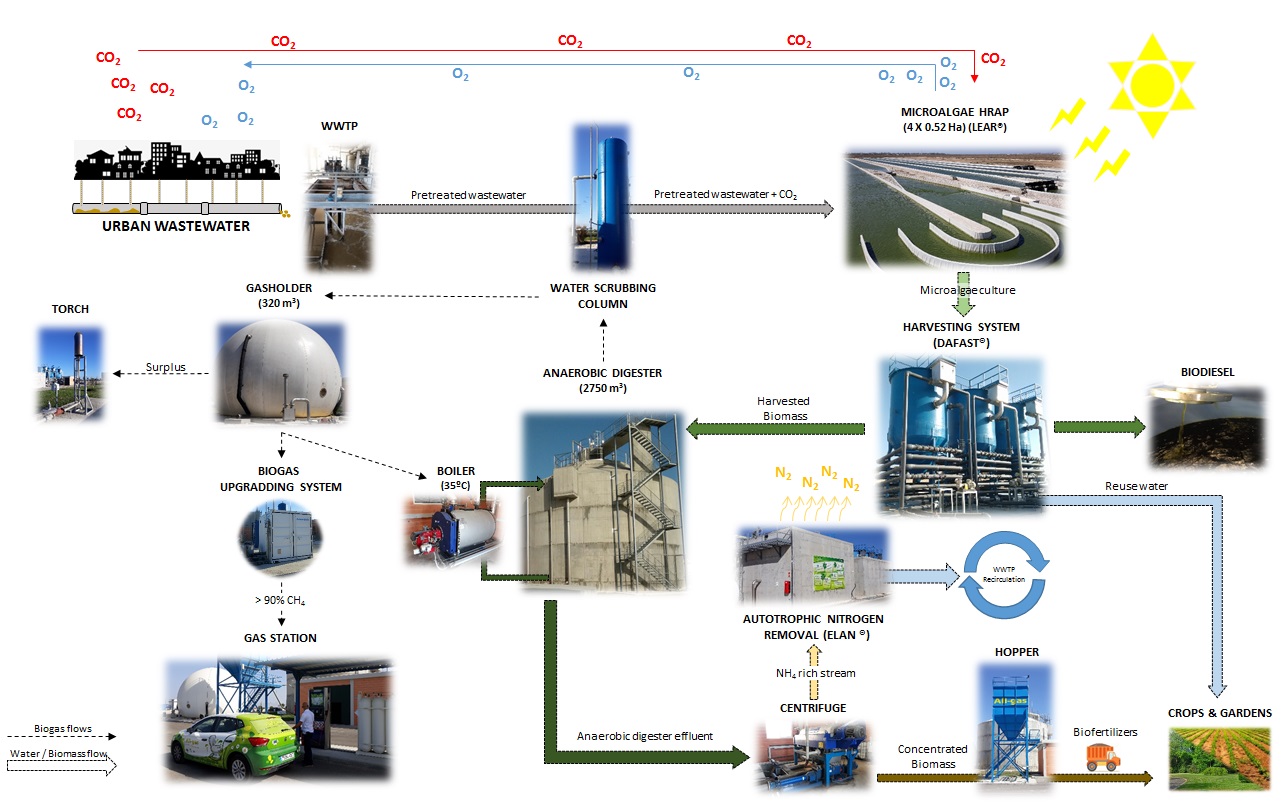

FP7 All-gas project demonstrates the sustainable large-scale production of biofuels based on low-cost microalgae cultures using municipal wastewater. The full chain of processes from algal ponds to biomass separation, processing for downstream biofuel production and purification, as well as the use in vehicles, will be implemented at up to 4 ha site.

The specified algae yield close to 100 t/ha/yr is obtained by integrating and upscaling innovative systems to double algal yields or decreasing energy consumption with novel raceway design. If a net oil content of 20% could be extracted with compatible characteristics for conversion to FAME, enough biodiesel yearly to run close to 20 cars could be expected per hectare of cultivation. Algae oils will be processed by a consortium partner to demonstrate its use in a motor test bed.

The residual algae is digested, together with wastewater and its solids, in order to produce biogas and CO2. The biogas is purified and compressed to serve as vehicle fuel, with an estimated yield for another 20 cars (roughly equivalent or superior to the potential fuelled by liquids) per hectare of cultivation.

Simplified flow scheme of the All-gas project